Liquid error (sections/image-banner line 171): invalid url input

Liquid error (sections/image-banner line 171): invalid url input

OneLaser Blogs

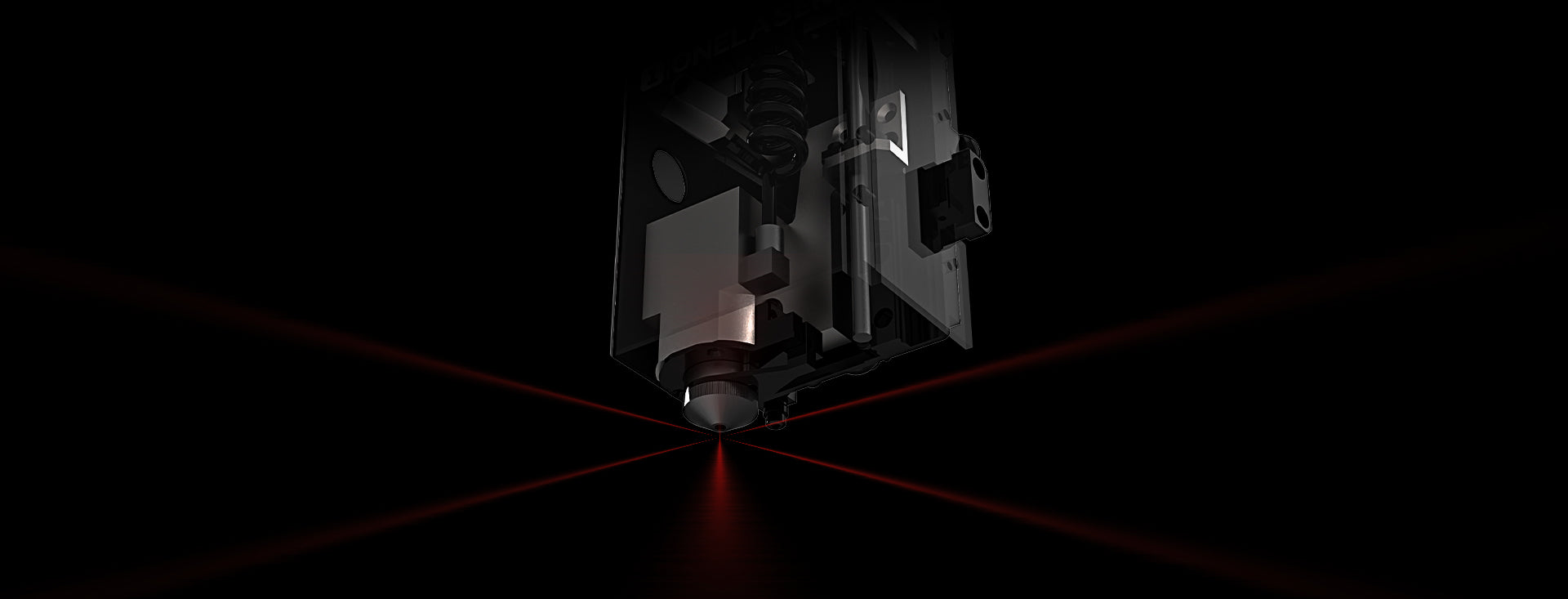

Image bannerStay updated on the latest innovations, discover expert tips for perfecting your laser engravings, and get advice on choosing the best laser machines. Whether you're a hobbyist or professional, we've got everything you need to elevate your laser engraving experience!

Give customers details about the banner image(s) or content on the template.

[

]